New application of spring bottle blowing process

After darth Victor machinery technology of exploration and research and development, found the type spring bottle (figure 5) completely the injection process can be used in processing.

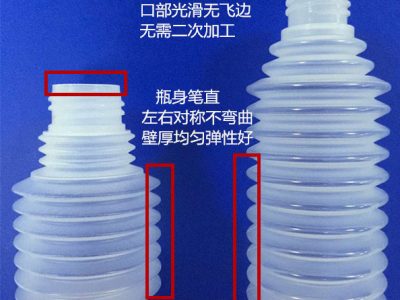

Bottle blowing spring uniform wall thickness, elastic feels better, elegant appearance, mouth also keep blowing consistent size accuracy, the advantages of good sealing.

For manufacturing enterprise, the injection production is a forming, no redundant material floolwing need secondary processing, avoids the pollution source in the process of production, but also saves the cost of materials and artificial cost.

MSZ30 machine, for example, 100 ml of LDPE spring bottle, a mold cavity 5 gram weight 8.2 grams, daily output 36000, energy consumption is only 15 degrees per hour.

Because such spring bottle is disposable items, market demand is very big, on the premise of guarantee the product quality, Victor machinery also keep trying in lightweight, will redo the lighter, cycle shorter, to further improve the production efficiency, reduce costs, to meet customer demand.

Current pharmaceutical industry integration and change is in full swing in progress, innovation is chasing every practitioner, a simple way of processing innovation, can improve the appearance of the consumer experience, improve product quality and function.

In addition, still can bring another unexpected benefits, low processing cost, product profit increase.

Believe in the production of injection spring bottle will inevitably become the mainstream in the market, the market leader.

江苏维达机械有限公司

电话:0512-58441128

邮编:215611

传真:0512-58432128

E-mail:[email protected]

地址:江苏省张家港市塘桥镇华芳南路1号